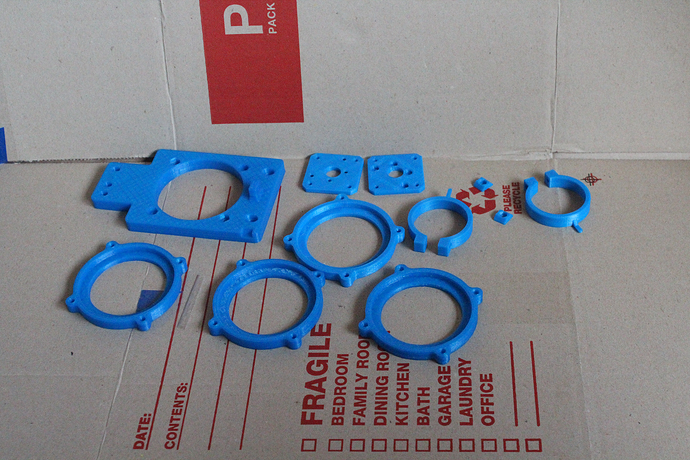

My parts where printed with my bog standard settings, specifically 3x wall layers and about 20% infill, varying with honeycomb infill to cross infill as a result of changing from slic3r to cura

Should be plenty strong hopefully

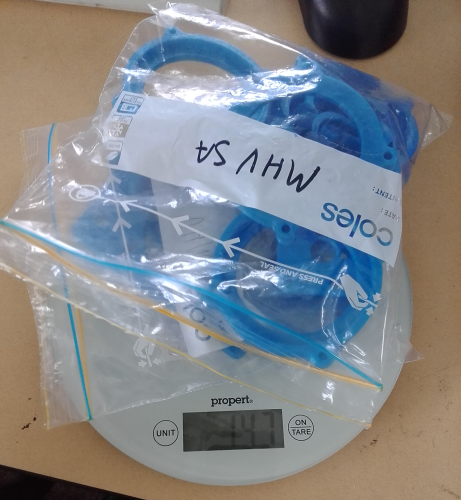

More parts arrived for me printer so hopefully I will get some progress tonight on raining stuff in.

King of random on YouTube has a good tutorial on making a DIY foundry that runs on coal or gas. He is American so the gas stuff might be a bit hard in cotton wool Australia. He also covers how to setup the casts with his method which is lost foam casting.

The forge is made with two cans (the inner can is removed, its purely a form) and a 50/50 mix of plaster of Paris and play sand. Would love to know whether this is a good idea or whether there are problems with the design.

For casting ally iirc we’ll need to oversize by about 11% as that is the shrinkage rate You’ll need to use natural pla ideally for the firing of the cast if we do what’s known as “lost pla casting” which as the name suggests is a lot like lost wax casting.

Prob a good idea to make sure actpg/act epa has no problems with it, particularly if we go down the coal route. Gas should be fine, though will need to see if two 7kw torch heads have enough bite to melt the ally any time this century, I’ve melted ally foil as a kid with a butane blowtorch but it took forever, granted it was a little toy blow torch compared to the ones I own now-a-days.

I have one the space can borrow, runs on LPG though purging the hose is a pain. (on the 500 watt nozzle it takes about 5 minutes to depressurize the hose, with the 7kw nozzle it takes about 30 sec or so to “burn out”)

Gas will definitely melt ally though as @clixx_io it’s prob cheaper/more efficient? to use coal and an air blower

With the cooler weather this would definitely be enjoyable vs doing it in the middle of summer

This is definitely something on my bucket list

Ta,

Max

p/s sorry if grammar and formatting are a bit screwy, I replied via my phone which for some reason discourse didn’t like, so I had to copy and paste it and then fix the broken line breaks

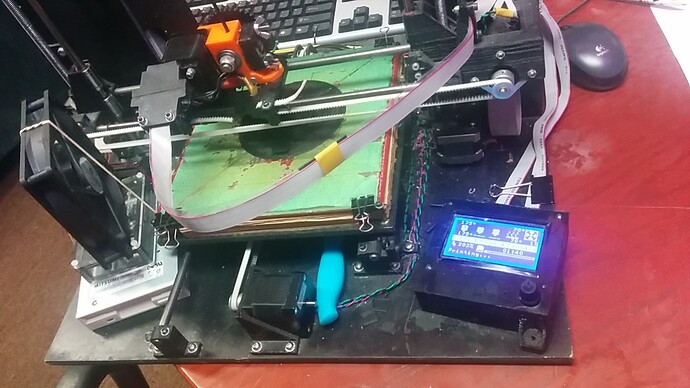

Like doing a curve, then warping to the otherside of the print, doing another curve then warping back, instead of doing it in one big smooth curve

Like doing a curve, then warping to the otherside of the print, doing another curve then warping back, instead of doing it in one big smooth curve

(metal Y carriage and a Wade extruder so I can use all of my 200mm x 200mm). It did appear to kinda sorta come good but still a bit sketchy.

(metal Y carriage and a Wade extruder so I can use all of my 200mm x 200mm). It did appear to kinda sorta come good but still a bit sketchy. maybe even sooner

maybe even sooner

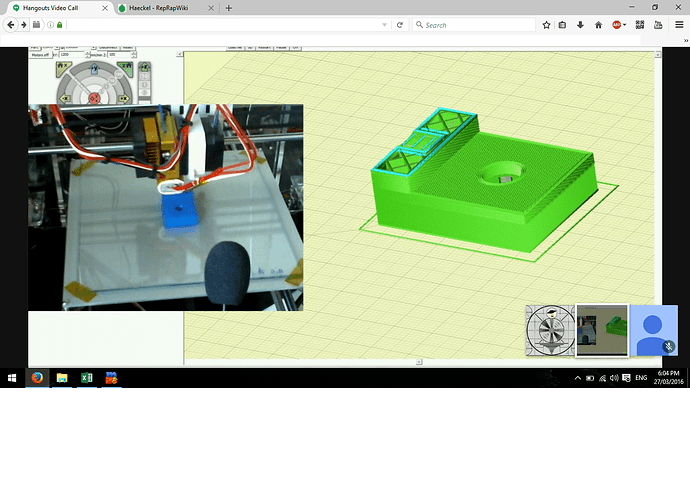

I’m basically waiting on parts, hopefully I can start staring at the mess of Rotator bits to begin attempting assembly later in the week.

I’m basically waiting on parts, hopefully I can start staring at the mess of Rotator bits to begin attempting assembly later in the week. it sagged alot, even with supports, leading me to believe my Z axis is a little screwy, which isn’t a major issue, unless I print tall parts.

it sagged alot, even with supports, leading me to believe my Z axis is a little screwy, which isn’t a major issue, unless I print tall parts.