Hey darling lets take the kids to makehackvoid for some fun

While the ducks had a family day out, we used the Taz to print parts for a weather station. I selected this one

Stevenson screen for weather station by kowomike - Thingiverse

and printed these

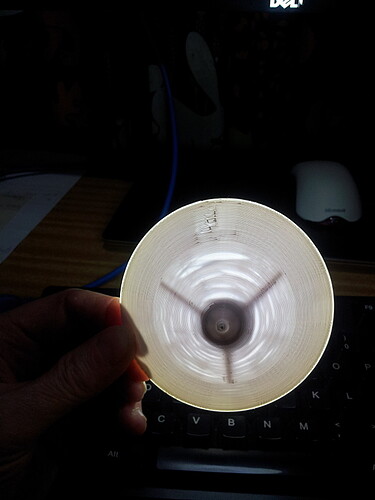

At home I examined the roof part, initially checking it against a flashlight

It is clear that there are issues. We did notice, at printing time, that some of the (internal wall) layers did not fuse properly. This is what it looks like from inside.

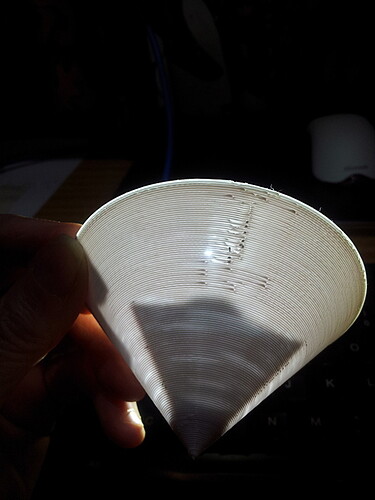

I then looked more closely at the uneven area

One can now see that there are actual openings (note a bright spot), not just thin areas. The uneven area examined here is where the printer moved to/from the other part (we printed a top part and a bottom part at the same time). This is a different problem than the un-fused traces closer to the tip seen earlier.

I can probably fix this, and any rain leaking in will probably run along the cone and drop outside the cage. But I am interested in understanding why this is happening and how this can be avoided. Maybe a higher fill rate (we used 20%) will work? Maybe standard speed (we used a fast rate) will be better?