As per the discussion at tonight’s meeting, the committee decided against using corded hand tools in favor of using a battery only system. It is thus necessary to decide which system should be used, before funds can be allocated to any specific tools. Discussion regarding these systems can be had here, and all arguments will be presented to the committee for discussion and approval.

Aldi system:

Aldi’s tools have been presented as a cheap option for stocking MHV, with batteries cheap enough that each member would be able to keep and bring their own batteries to the space, if they desire.

Their selection of tools, however, is limited, and seldom available, making replacements hard and the aquisition process a long one.

As the range of tools would be limited, we would have to fall back on to corded tools, which, due to the nececity and frequency of tagging, has been decided against. The only viable option with this would be to get certified, and the needed equipment, to perform test-and-tag service ourselves. From memory, for the price to do this, we would easily be able to buy a large number of tools from even one of the more expensive brands.

Ryobi One±

Everyone’s favorite brand, Techtronic Industries never fails to surprise me, so long as I always come in with low expectations.

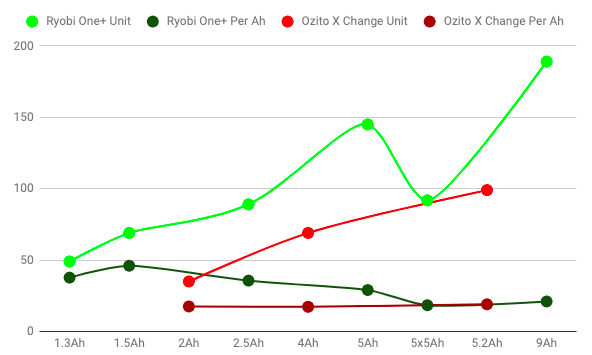

Individual batteries aren’t cheap, but if we don’t mind stocking up on drills, batteries shouldn’t be an issue. $200 of drill will get you a 1.5Ah and a 5Ah, if bought in 5 packs the 5Ah’s are $90.

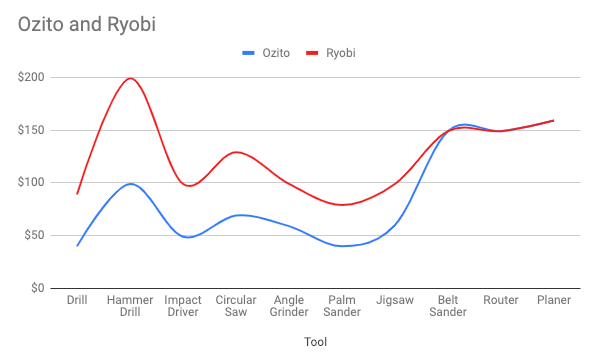

Skins range from $60, averaging $99, hitting $200, with some specialty tools getting near $300.

Availability isn’t an issue, they’re not going anywhere, and all tools that have thus far been proposed, I believe, are available.

I will spreadsheet this all up to get us prices.

I want to clarify this is for when we are buying a tool we don’t already have or replacing one that is broken, right? In the interest of not going backwards we aren’t considering burning money on new tools solely because the current ones don’t have batteries.

https://www.bunnings.com.au/our-range/brands/o/ozito-power-x-change

Batteries are $35/$69 for 2/4Ahr

Pros

Aldi prices,

many more tools than aldi

always available

Cheaper than ryobi

Cons

slightly fewer tools than ryobi (eg water pump)

My overwhelming experience with tools is that you get what you pay for. I still have a Makita battery drill purchased 30 years ago. Last used a few years back, original battery still working and holding a charge. Purchased a more capable Bosch drill some years later and the batteries struggled to last 10 years (light use).

My experiences with Ozito have been poor. The only redeeming grace is their 2 year warranty. By all accounts the brand is popular with tradies (they always keep their receipts).

Ryobi is probably a better choice. Has anyone used one of their battery products hard? I.e. home reno or work situation?

I’d like to think space equipment will be used a little more frequently than most DIY tools.

in my experience I haven’t found ryobi to be worth the 50-100% more than ozito, tyey both work, but break after a while.

mhv is where tools go to be abused and die. Its easier to get $50 of value out of something than $100 before it dies, is lost, or stolen.

Well… that’s a thing that needs to change.

My checklist for the tools that, if available, would make a battery type suitable are Electric Planer, Hammer drill, impact driver, angle grinder, and belt sander.

These are all things that some of the smaller ranges don’t have, so it’s a good marker to tell if a range will be too anaemic to be of any use.

While Ozito does have orbital palm sanders, they don’t have battery belt sanders. They also do not have a battery planer.

As these are tools more-or-less essential to the space, not having them means we’d either go without, or resort to corded tools, so they’re in much the same situation as the aldi option.

I personally use Ozito myself, but I considered them for the space, but brushed them off.

Both Ozito’s X-Change and Ryobi’s One+ are 18v, so one option could be buy Ozito tools and batteries, for what they supply, then, if we need something like a Ryobi belt sander, use a 3D printed shim to connect the Ozito battery to the Ryobi tool.

Something similar was suggested for Aldi, but I think the more native tools available, the better.

I agree this is far from ideal, and maybe more respect for the space could be fostered over time.

But I’m not saying anything new. Everyone has seen the condition of, well, almost everything at MHV.

I am just explaining the reasons why to me it, increasing spending with the expectation of better tools and longer life spans in an environment not conducive to such dosn’t add up.

To answer the question of is this a replacment thing then the answer is yes. There is no need to be running out and replacing working tools however as new acquisitions are out heaed and replacements are made it would be good to have a single direction to be heading in. There is no point in haveing multiable battery systems in the space.

I’m currently graphing and pricing getting set up with multiple battery systems, to compare Ozito’s X Change to Ryobi One+, however as it seems the committee knocked back damn near every ******* tool that was suggested, I’ve taken a short inventory of the space, any tool we currently have that is now broken is going on the list. Any tool that will most likely die soon, or is in partial disrepair, is going on the list. Anything that had any interest whatsoever on the weekend is on the list.

If you wanna argue that we should just throw out a bunch of broken tools without replacing them, be my guest, but you better come up with a damn good argument as to why it’s better we have $2k sitting in our account, preallocated, doing nothing, because we’re too damn perfect to lower ourselves to spending $150 on a planer. How could we do something so vile, to BUY a PLANER?

What are we, some sort of woodworking facility? Never!

There’s no point even having this discussion when the only tools the space is actually looking at buying is a Drill bit sharpener, a belt Sander, half a router, an Impact Driver, and a Nibbler.

Consider that two of those can be purchased cheaper off an air system, and this all seems rather silly.

None of our four battery drills work. Our hammer drill has a broken clutch. Our mouse sander is dead. Our belt sander is broken. Don’t get me started on the routers.

“There is no need to be running out and replacing working tools”

Consider that if we just replace what’s broken, I could easily spend $500-700.

Something I’d like to throw to the committee, once we’ve settled on a system, is automatic approval to replace broken tools without needing individual authorisation, so long as there is money left in the $4k tool grant.

I don’t wanna have a discussion about why we need to spend $69 on a palm sander when we’ve already bought one in the past, used it so much it’s scuffed up to oblivion and burned out.

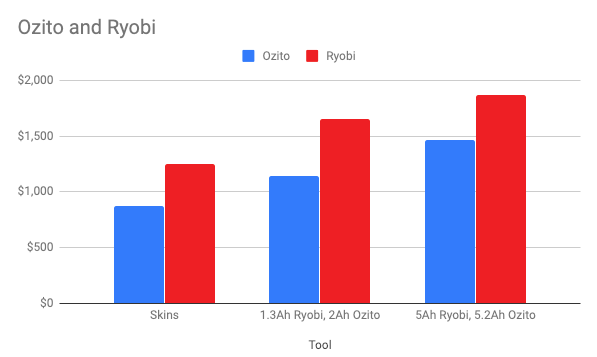

Raw Skins, $873 vs $1250

And here’s pricing with batteries. From Ozito to Ryobi, not even a 25% cost reduction.

These sets include 5 batteries of the listed type and enough chargers for all of them.

Further cost savings can be had by buying bundles, but I’ll only optimise further once a set has been decided on.

Heck, I didn’t even post the raw battery costs!

Nice graphs Ryan,

For your more stream lined tool authorisation system, how about a thread on the forum similar to the way we have a key holder nomination thread.

Members could put up a request for something, and then if the majority of the current committee respond in agreement the member can purchase the tool and submit the receipt to MHV for reimbursement.

This way there is a record of everything, the member can state details about cost and need, the committee can decide how much MHV contributes, and the receipt goes to the treasure for safe keeping when the item needs to be returned to the store in future.

Can you please watch the way that you say things?

Particularly in a public forum, but at all times.

For the record, you are a member of the commitee also.

It strikes me that the workshop in general suffers from being poorly organised.

Suggest that as a priority we initiate some short projects such as:

- more tool boards for the walls (most tools piled on LH corner table). Making french cleats from some of the pallets would do it.

materials: pallet boards, 12mm ply, screws, rawl plugs, paint

guesstimate effort : 1 hr per sq metre of wall space

- Machine cabinets. The only way to make a small space machine friendly is to put the machines on moveable benches or trolleys. As a general rule have some drawers underneath to hold any consumables.

materials: 90x60 pine, 16mm MDF or ply, biscuits, glue, screws, castors, paint or varnish

guesstimate effort: 8-12 hrs/cabinet

I went into Sydney Tools today to have a poke around and had a discussion with their guys about tools. Now stepping into the tradesman level of tools he recommended either Makita or Milwaukee. He also thought that brushless was a better choice given that it has a 40% higher life expectancy of the equiverlent brushed took.

If we were going to focus on wood working he sudjested Makita however he also said that the Milwaukee extended range was better, this was becuse their core range had more to begin with and their 18v range was compatiable with the 12v range. Also they had some fairly funky battery charging stations. I will attach the quote for the kit I looked at, yes it was a bit of an investment but we don’t have to buy it or if we do we could do some fundraising. The more I think on it the more I think

I do think that a good battery platform could solve a lot of the power issues in the shed.

cust 678035 quote7702442.pdf (6.6 KB)

However something like this may be a better choice Esspessally if we invested the cost difference in a battery station

Anyhow food for thought.

Hi Ben,

my gut feeling is to:

- buy a set of ‘general’ power tools

- not favour any one hobby stream e.g. woodworking

As a basic set suggest battery tools:

a) drill with hammer function

b) impact driver

c) angle grinder

d) circular saw

e) random orbit sander

I personally own a reciprocating saw, it doesn’t get used much. I don’t cut much metal. Same goes for the planer, can be hard to get right, often better off using a jack plane.

I’d add to this list:

f) a set of quality twist drills in 0.5mm increments

g) modest drill sharpener, not a $50 ‘special’

h) impact driver bits

i) spare TCT circular saw blade or two (need to rotate through sharpening service)

I’d regard consumables like grinding disks and sandpaper to be the makers responsibility.

Thoughts anyone?

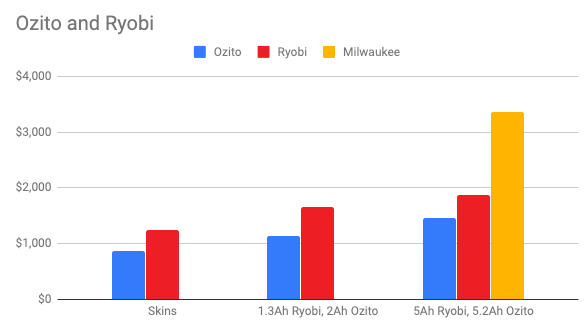

Compared to the baseline of tools I’ve been using, Milwaukee is over twice the cost of Ozito, and getting close to twice the cost of Ryobi.

Do consider that with both Ozito and Milwaukee we’d still need to buy some Ryobi tools and use adapters.

Here’s the graph, the only extras we’d get with the Milwaukee are a Reciprocating Saw, aLED Work Light, a Worksite Radio, and a bag.