If the source of spare stepper motors doesn’t work out (or even while you are waiting to find out), please post the specs of the motor, i.e. approximate size, step size, coil resistance and current rating (and inductance if known) as I have a much too large collection of old steppers, mostly of the correct vintage, and I might have something that would do.

Hi Chris,

thanks for your kind offer. Need to wait and see how the US offer pans out.

All,

looks like my contact Dave in the US is coming good with his offer. Expect to have two steppers available for pickup in Ulladulla around the end of the month. Best part is no charge either for the motors, “free to a good home”, or the transport to Australia (Dave’s friends luggage).

If anyone is going to be in the Ulladulla area early November and is willing to pick up the motors could you please let me know via private message?

Hi all,

Dave in the US has come good and there are now two Emco steppers waiting for pickup in Ulladulla. If anyone plans on visiting the area in the next two weeks and is prepared to do a pickup could you please let me know via PM?

Thanks,

Stephen

Current status on this is that the stepper motors are still in Ulladulla. Unfortunately Neville, the keeper of said motors, didn’t end up making a trip to Canberra this week.

@ian has indicated he may be in the area in a fortnight. Will keep you posted.

@RyRyPrime and I attempted to connect @spanner888’s LCD TV to the lathe tonight using composite video. No joy unfortunately. Will try again next week.

Thanks to @spanner888 organising a pickup the stepper motors arrived last Wednesday. I replaced the broken motor and am pleased to report that the lathe now has working X and Z axes.

Yeay! Made anything yet? Photos?

Not yet. Tool changer is still in the cupboard. It needs to be stripped, cleaned and lubricated before being reattached. Once that’s done the question of tooling needs to be addressed.

The automatic tool changer uses carbide inserts. Right now we have a right to left cut tool (facing) and a threading tool. The RL tool is a workhorse and has 1 unchipped end. Don’t imagine the threading tool will get a huge amount of use. It is also chipped on one end. A new LR tool is needed but may be expensive, Emco spares are a high end item and uncommon.

We may want to consider replacing the auto toolchanger with a quick change toolpost (Chinese). The upside would be cheaper, readily available parts. The downside would be manual toolchanges.

Other items on the to do list are

. Dust cover

. Trolley

. Display screen

Progress Report #?

with Ryan’s help connected up an old plasma TV and checked the video was working. Makes it SO much easier to enter CNC programs.

Recent progress. Whilst the old TV works using the very dated composite video signal it is way too big to be attached to the lathe. It also has a lot of screen jitter.

@spanner888 and @crashman39 have kindly provided much smaller, portable tv screens. Unfortunately one doesn’t recognise the non standard signal and the other has yet to be tested.

In the mean time I have been amusing myself attempting to create a video upscaler using an FPGA. The idea is to hack into the existing video board, extracting some key signals so that the old screen can be sampled and then played back as a VGA signal.

https://ketturi.kapsi.fi/2017/10/reverse-engineering-emco-cnc-video-controller/ makes for interesting reading.

Upscaler you say? I can use one for the Amiga. It has a 15KHz output that needs a non-standard (today) screen. Upscaling to VGA will be nice. You may take a look at some Amiga solutions where one simply double the lines (I think), e.g. the GBS-8220.

Hi I’m new. Just had a tour of the workshop yesterday. Pretty interested in this cnc lathe and the other cnc engraver.

I ewe lots of discussion about the video out. What’s the latest on the lathe?

Hi @JayChow,

all motors and electronics are working. The tool changer and guard are in a cupboard but can easily be reattached. The cross slide gibs need a tune up.

We are short on tools in general and the jacobs chuck key is in poor condition. From memory we have two carbide insert toolholders, one or both inserts are damaged and need replacement. IMHO we’d be better off using HSS tools, easy resharpening etc.

We’ve had limited success getting the video output to work. It’s a 1980’s vintage PAL signal, difficult to get a monitor to match these days. Monitor displays 10 lines of Gcode at a time. Without it, you are able to see only one field of a single line at a time.

It has an RS232 interface, so in theory you can upload/download CNC files to and from. The RS232 connector is some kind of round mil-spec type. One project is to replace it with a standard 9 pin d-type.

Bottom line is that it works. I’ve used it to bore holes but not actually turn anything. The machine accepts Gcode if you manually key it in. You can attempt to turn using manual jogging.

I’ve stalled on it at them moment but could be coaxed into action.

Cheers,

SteveD

Thx Steve, Amourer said you are the best person to speak to about the CNC lathe.

I got a small basic CNC engraver at home (aluminium frame). Would like to use the lathe to turn some custom wooden chess pieces (cannot be done on a standard lathe).

I’m not good with electronics at all… Is the RS232 just for file transfer? Can the lathe be driven from a more modern computer instead? Inputting gcode into the console doesn’t sound like a feasible option for what I have in mind.

Hi Jake,

the lathe is perfect for that kind of job.

RS232 is also known as a serial port. It used to be standard on most computers but is disappearing rapidly. You are correct, normally you’d do your design work on the PC using something like Fusion 360, generate the GCode and then download it to the lathe using the serial port.

At the moment there are two options:

- Replace the round mil spec connector with a DB-9 socket (metalwork and soldering)

- Mount a serial breakout board (FTDI type) inside the chassis, i.e. USB to RS232 (complex)

Option 1 is pretty straight forward, the down side is that most people are unlikely to have an RS232 port on their laptop anymore and most won’t have a USB to RS232 converter cable handy.

Option 2 is more complicated and involves some electronics but may be a better idea in the long run as it puts the USB to RS232 converter cable inside the unit. @Harvs donated some PCB making tools and material to the space the other week. This would be an excellent little project to give them a tryout.

I see. Don’t think I’m of much help Re: those options.

Let me know if there’s anything else I can help with

Well it also needs a trolley and a cover made.

I was thinking a wooden or welded steel trolley with a couple of drawers for accessory storage to keep them out of the dust.

A cover could probably be made with plastic sheeting, duct tape and some edge weights or magnets. Wood dust is a problem and will gum up the works so sealing around the base somehow would be nice.

Yeah happy to help. Sounds like you’ve drawn up some plans already.

When will you be there next?

Hi @sjdavies

I meant I’m happy to help. But I live in Woden. Let me know when you go to the space. We can discuss the planned trolley and cover etc in person.

Btw, do you use the other jeweler’s cnc?

Hi @sjdavies

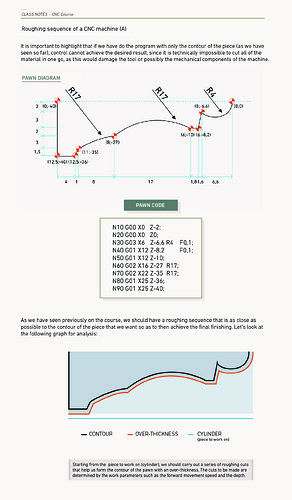

I use Fusion 360 as well. But don’t think the machines decades ago use such complicated codes. Did some more research (see attachment), seems like you can machine a pawn with only 9 lines of codes.